Welcome to visit Xinxiang Zhongxin Hydraulic Technology Co., Ltd. !

- Phone:0086-158 3617 7527

- Email:[email protected]

Welcome to visit Xinxiang Zhongxin Hydraulic Technology Co., Ltd. !

The end cap, as an important component of the filter element, is usually made by stamping or machining processes, and the materials include stainless steel, carbon steel, aluminum and other metals. Its design features include a certain depth of glue injection groove to ensure sealing performance. In addition, the radial end cap is specially equipped with an O-ring groove to further enhance its sealing effect.

The end cap serves to store adhesive, provide an interface for connection with the filter, thereby enhancing the end load strength of the filter element. It also acts as a link between the frame and the filter material, and is connected to the sealing element to achieve a good sealing effect.

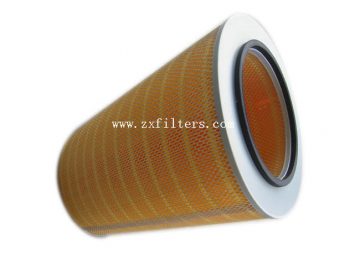

The design of the frame varies according to the strength and pressure that the filter element can withstand. The wall thickness is moderate to ensure the structural stability. Small holes are evenly distributed on the surface of the frame to facilitate the flow of adhesive and the support of the filter material. The frame is usually made of refined metal materials (such as stainless steel, powder-coated or galvanized) to ensure its durability and stability.

The frame plays a crucial role in the filter element. It not only supports the structure of the filter element, protecting it from pressure difference effects, ensuring axial perpendicularity and parallelism, but also reduces resistance to ensure normal operation.

The filter material is the core component of the filter element, and it is mainly composed of the filtration layer and the support layer. There are various types of filter materials, including glass fiber paper (divided into imported and domestic), stainless steel mesh, copper mesh, and water-absorbing filter materials, etc. The support layer mainly uses galvanized mesh, stainless steel mesh, plant fiber paper, or copper mesh, etc.

The selection of filter materials needs to be based on different materials and precision requirements. It plays the main role in filtering and ensures the filtering effect. If the strength of a single layer of filter material is insufficient, a supporting layer and a protective layer can be used to reinforce it. The operation methods of filter materials mainly include folding and wrapping. The core task of filter materials is to ensure that the filter can achieve its expected filtering efficiency and meet the set cleanliness standards.

The sealing elements play a crucial role in the filter. They are mainly divided into sealing gaskets and sealing rings. These components are usually made of soft materials and possess both compressibility and elasticity, ensuring the tightness at the connection between the filter element and the filter. Depending on different sealing requirements, the sealing elements can be classified as radial seals and axial seals to achieve the best sealing effect.

The bypass valve, also known as the safety valve, has a structure consisting of a valve core, valve body, spring, spring seat, and retaining ring. Once the pressure difference between the two sides of the valve exceeds the preset value, the base of the valve will automatically open, allowing the working medium to pass through the bypass, thereby ensuring the safe operation of the filter and the entire system. The bypass valve opens when the pressure difference exceeds the set value, allowing the medium to pass through the bypass and ensuring the safety of the filter and the system.

2025.09.29